Artificial Intelligence in the Chemical Industry: Unleashing Innovation | Deep Tech Briefing

Techs and Case Studies on how AI can be the catalyst for innovation in the Chemical Sector. Better, Cheaper, Faster.

The chemical industry is a pivotal component of the global economy, impacting various sectors from pharmaceutical production to materials science. The advent of artificial intelligence (AI) is poised to trigger a revolution in this sector, enhancing efficiency and productivity while reducing costs.

Forecasts suggest that by 2032, the market value of AI in the chemical sector could reach a market size of $17.9 billion, with a compound annual growth rate (CAGR) of 31.2% from 2023 to 2032.

“Industries like chemicals are focused on recombining nature’s molecules to invent exciting new things, and refine applications for existing products and components”

Stated Joshua Greenbaum, Principal at Enterprise Applications Consulting in a Forbes article.

“They can use generative AI tools to explore and analyze possibilities based on the company’s library of chemical compounds and factory operations. And unlike the humanities and other sectors where absolute parameters aren’t clear, the chemical industry can scientifically test LLM’s suggestions.”

Key drivers of this expansion include the demand for efficient and sustainable chemical production processes, advancements in machine learning algorithms and computing power, the growing need for predictive maintenance, and real-time process optimization. The increased focus on the research and development of new materials and formulations, along with stringent regulatory requirements necessitating compliance solutions, are additional factors contributing to this growth.

In the chemical domain, generative AI is employed in a variety of applications, from molecular modeling to virtual screening, process optimization to predictive maintenance, all the way to supply chain management. By analyzing vast datasets and performing complex calculations, AI algorithms can uncover patterns and correlations that would otherwise remain unnoticed, leading to the discovery of new materials, formulations, and processes.

During the Covid-19 pandemic, for instance, AI proved crucial for studying the structure of the coronavirus, its lifecycle, and infection pathways in much shorter timescales than would have been possible otherwise.

As technology matures, an increasing number of chemical companies are adopting AI-based solutions to maintain a competitive edge, accelerate research, and create more sustainable products and processes. Additionally, a recent survey conducted by IBM revealed that over 80% of chemical industry executives anticipate AI will be important to the success of their business in the next three years.

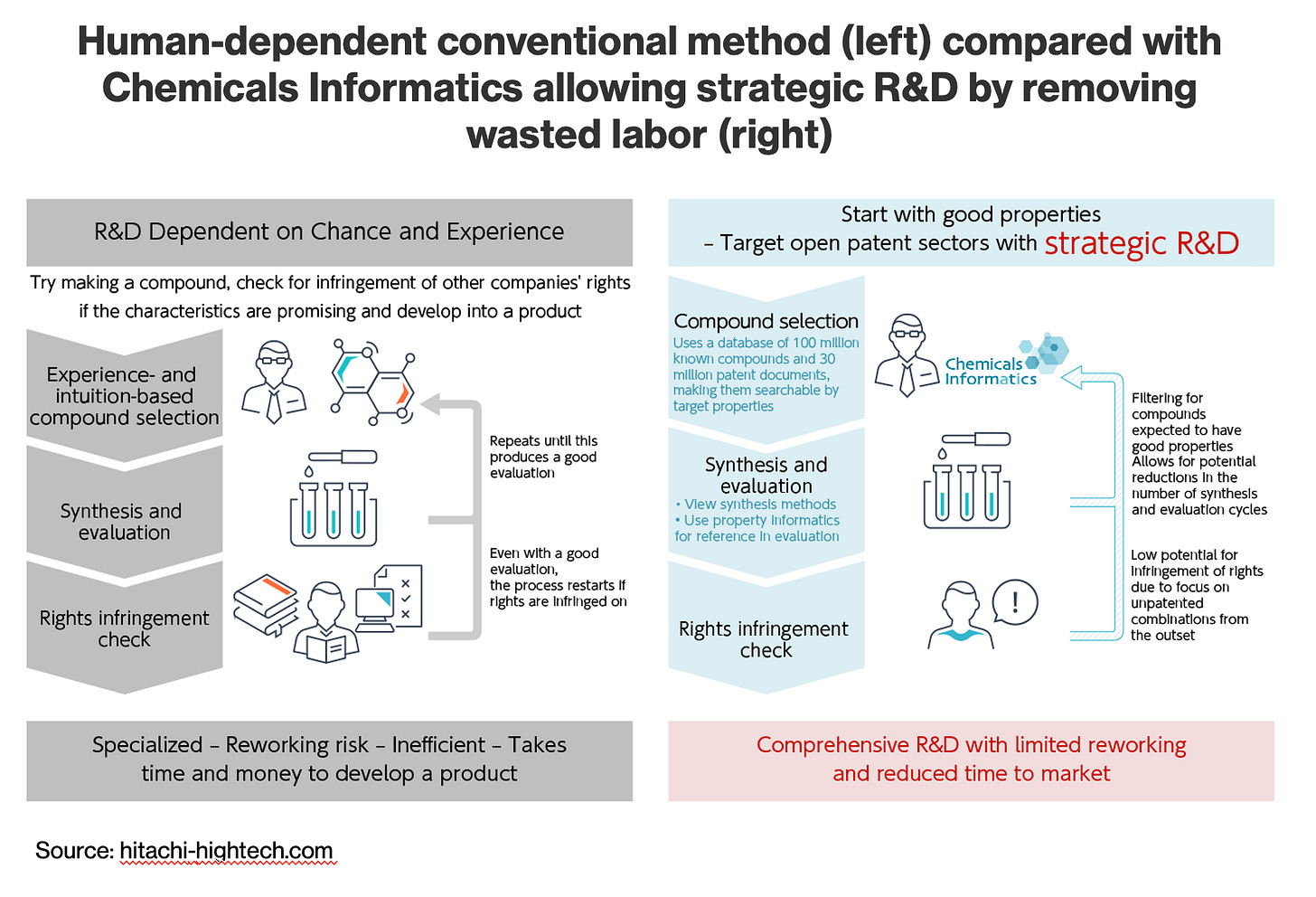

For instance, Hitachi has developed an artificial intelligence capable of identifying the key components for developing new materials.

With access to a database containing over 100 million records, this technology significantly accelerates the material development process, reducing the time and costs associated with research and development. For example, it reduced the time required to find additive compounds for biodegradable plastics from 120 days to just two days and effectively narrowed down the search for suitable solvents for lithium-ion batteries from an initial list of 10 million possibilities to only 90 ideal candidates.

Another example is the National Research Council of Canada (NRC), which, as part of a $2.5 million project, employs artificial intelligence to optimize the discovery of molecules with applications in the health and clean energy sectors. This approach focuses not only on identifying molecules for the development of eco-friendly materials intended for clean energy but also on environmental protection, including innovative technology for electric vehicle batteries or advanced methods for carbon capture and storage.

Harry Guo, Senior Research Officer at the NRC's Digital Technologies Research Centre, highlighted the revolutionary potential of AI in a statement released on LinkedIn:

“With billions of potential candidates, searching for a particular molecule can be like looking for a needle in a haystack. AI has the potential to cut years off this search”

"Through exploration and active knowledge-seeking learning algorithms, AI can learn from both the data and experience when, where, and how to explore the search space in order to better guide the molecule search."

Despite the promises, A recent article in Nature argues that for chemists, the large-scale AI revolution has yet to happen, due to the lack of data available to feed the data-hungry AI systems.

“If chemists want to harness the full potential of generative-AI tools, they need to help to establish such training data sets. More data are needed — both experimental and simulated — including historical data and otherwise obscure knowledge, such as that from unsuccessful experiments.”

This is because generative AI models rely heavily on large, high-quality datasets for training. However, acquiring such datasets in the chemical industry can be challenging. Data on chemical structures, properties, and reactions can be limited or proprietary, making it difficult to train accurate and reliable models.

Nevertheless, the potential on the horizon is extraordinary.

The chemical industry has much to gain from the use of AI, not only to accelerate research and development but also to create more efficient and sustainable processes.

Generative AI is emerging as the catalyst that could usher in a new, grand era of innovation in the chemical sector, offering powerful tools to tackle contemporary challenges and pave the way for a more sustainable, innovative, and opportunity-rich future…

Technologies Unwrapped

According to a GlobeNewswire report, the principal application areas for AI in the chemistry and chemical industry include research and development (74%), manufacturing (61%), forecasting and planning (47%), and risk management (58%).

AI practiced in chemistry research was motivated primarily to accelerate drug discovery while reducing the massive expenses and time to launch new pharmaceuticals. In addition, AI can predict future material costs making the manufacturing process more marketable and significantly reducing the company's losses.

It's in doubt that AI in chemistry is a growing trend so, for a more profound understanding of this phenomenon, it is crucial to comprehend the leading technologies that drive this "miracle."

Let's dive into it...